Central dried air for drum dryers

and other installations

|

The air drying process is an expensive business; this applies not only to condensation and adsorption dryers, but also to the hybrid dryers of energetic interest (combined condensation and adsorption drying). It is not economical to place an air dryer at every drying installation. Continuous drying does not take place at all installations, and dried air is not required constantly.

On the right: Central hybrid air dryer |

|

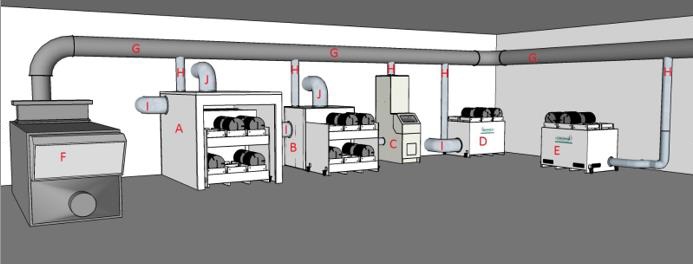

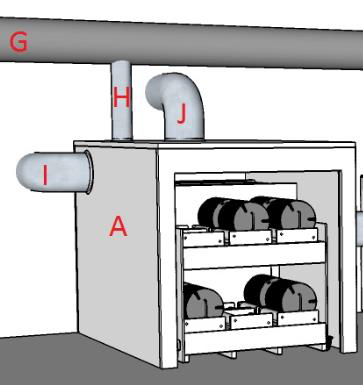

Agratechniek has developed a principle at which a central air dryer (F) brings the dried air to where it is needed. Various drying installations, like a closed drum dryer (A), open drum dryer (B), individual drum dryer (C), mobile drum dryer with outside air (D) and mobile drum dryer with inside air (E) are connected to a central air duct (G). Thanks to the advanced ABC process the dried air is discharged automatically to where it is needed at that moment.

During the seed drying process, a lot of moisture can be discharged using heated up outside air. Unfortunately the conditions of the outside air are not always suitable to reach the desired equilibrium moisture content at the end. Especially now that more seed companies want to receive, store and package the seed with a lower moisture content. To be able to dry the seed quickly and successfully, dried air is needed in the last phase.

It is therefore not necessary to have each drum dryer provided with an air dryer!

|

At the start of the drying, outside air (I) is usually dry enough to absorb a lot of water. This outside air is therefore warmed up to the desired temperature and blown through the seed. Wet air from the seed is evacuated outside (J).

During the drying process, dry air can be added to the process air (H). The seeds can then be dried to a low moisture content. As long as the air from the seed contains more moisture than the outside air, this air is discharged. When this air becomes dryer, it will be recirculated and the final moisture will be absorbed by the dried air. |

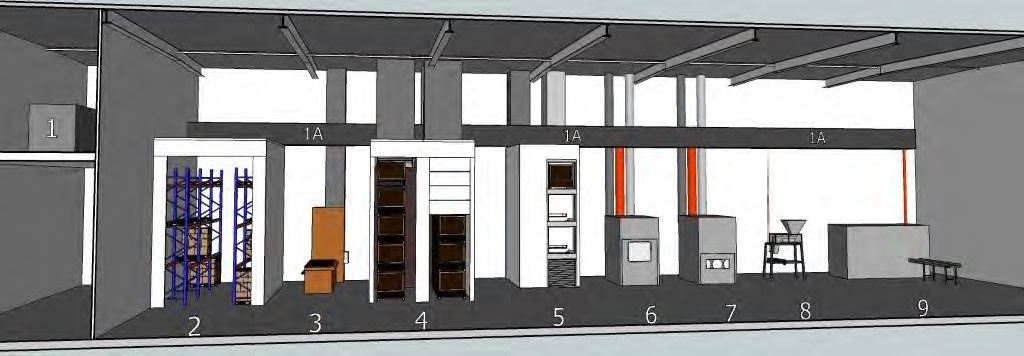

The central air dryer (1) brings the dried air by an airduct (1A) to where it is needed. Conditioning cells (2), drying tables (3)Various drying installations (4, 5), cabinet dryers (static (6) and rotary (7)), or packing machines (8,9) can be connected to the central air duct (1A). Thanks to the advanced ABC process the dried air is discharged automatically to where it is needed at that moment.